Design Process

Our Design Process:

A customer needs a tank … that’s you.

The first thing you must decide is what type of tank you need.

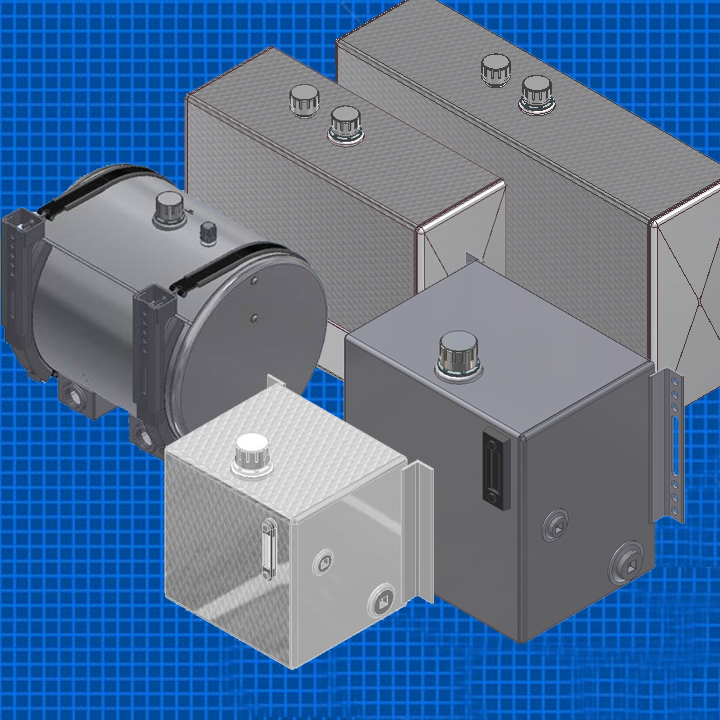

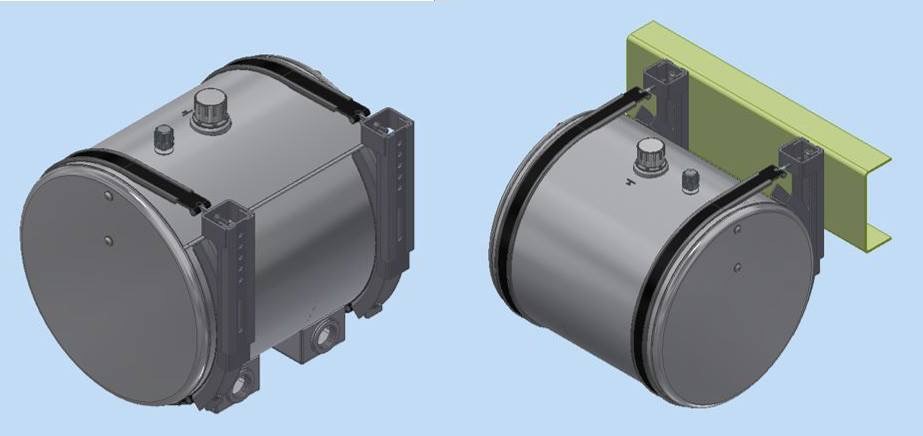

The most common types we manufacture are Hydraulic, Transfer and Reefer.

After you decide what type of tank you need, send us a marked-up drawing of your proposed tank with detailed dimensions and labels for porting and other features.

Our engineering staff will assign a model number to the proposed tank assembly.

The tank assembly will be separated into two sections; manufacturing and post “leak-tested”. This is done to help identify the manufacturing process against all secondary procedures such as finishing and packaging.

Both sections of the tank assembly are modeled up in AutoDesk:Inventor with all individual parts named, numbered and identified.

The model is priced, a cost is determined based on the bill of materials and an estimated time to produce. (Construction of tank will not begin until design has been approved AND a purchase order has been received)

Once price is identified, the design and quote are submitted to you.

If you would like to submit any changes, depending on how radical the change, the process may have to start completely over, or may only need to be tweaked.

After you approve the design, the model is ready to be ordered. **Machine programming is not completed/encoded until the model is ordered

Once you submit a purchase order, a lead time will be confirmed.

Standard lead time for custom tanks will depend on complexity of design.

Our Design Software:

- Inventor: profession-grade mechanical design and 3D CAD software for product development and product simulation.

- AutoCad: software for 2D and 3D CAD with various specialized toolset and apps.

Merry Mechanization SMP/IS Sheet Metal Programing Software

American Mobile Power is constantly striving for modernization and better process flow. We continually add new/better equipment to increase output and improve quality. We are actively developing new solutions to improve our team and to satisfy our customer's needs, this allows us to stay competitive and adds value to our team and customers.